0555-6768298

0555-6768298

0555-6768298

0555-6768298

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

Contact Us

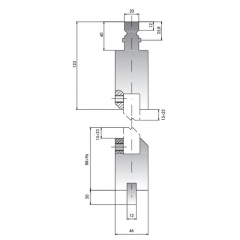

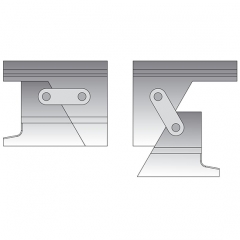

Also known as Z bends or Joggles, the Offset punch and die set is able to make two bends at the same time. This is the solution for applications requiring materials to be joined together or when you need to make a second bend that will not interfere with the first bend.

Advantages ▶ Easy and quick bending of boxes ▶ Easy removal of the finished profile ▶ Compatible with punches/top tools ▶ Individual production possible

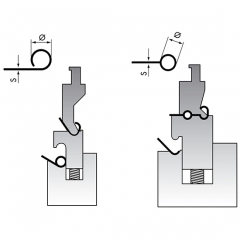

Advantages Production in two or three strokes Reducing of marks through spring loaded hold-down-device Active components are hardened High repeatability through integrated backgauge Functional test and adjustment through test bends - with your sample sheets Suitable For Material thickness up to 4,0 mm minimum inside Ø: 2,5 mm x material thickness for steel and aluminium 3,0 mm x material thickness for stainless steel

Tonnage 150 kN/m max. Material 42Cr: 900-1150 N/mm2 Advantages - Bending of closed profiles can be produced - Large Channel Profiles can be produced - Easy Removal - Individual Production

Press brake rolla-v dies without scratch, it's best to put the film on the workpiece surface when you bend. and we will recoomend the suitable roll-v die size for you according to the plate you bend.

Shim Style Adjustable Dies Adjustable lower dies could be considered to be one of the most versatile additions to a press brake. With this type of tool, openings can be arranged from 6.35mm to 381mm. Spacers are provided to produce the required opening. Slotted spacers allow for easy removal to change the die opening. When not in use, spacers are positioned at sides of the die block. These dies can be furnished in solid lengths or sectioned for easier handling.

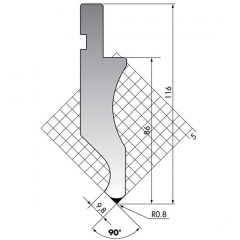

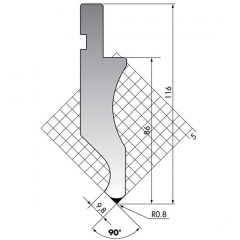

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

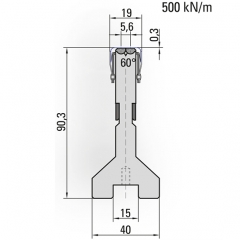

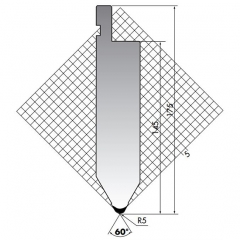

The stright blade size:835*175*40mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

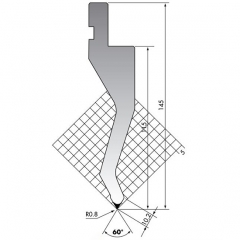

The stright blade size:835*145*32mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

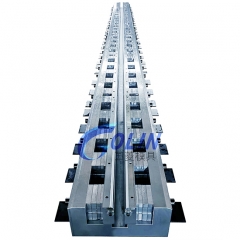

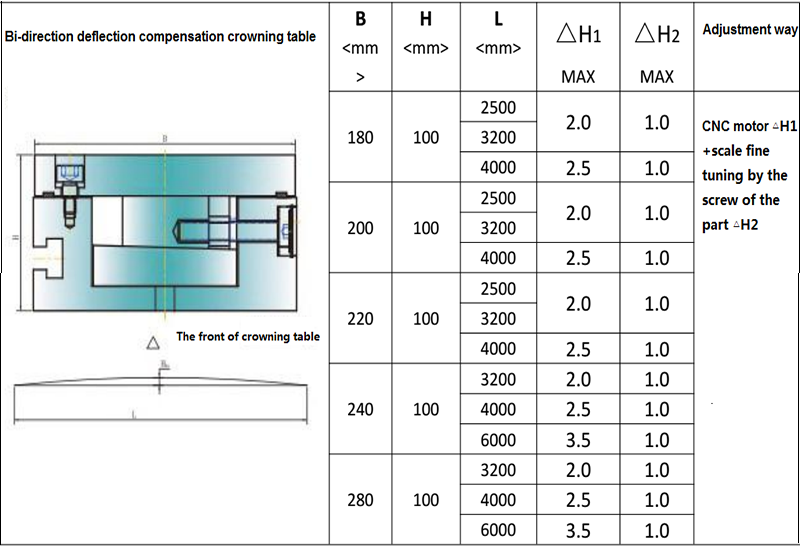

The structure of the press brake reflection compensation crowning table can promise the bending precision for angle and strightness when you bend the workpiece

product origin:

Maanshanbrand:

Golinshipping port:

Shanghaicolor:

Silverlead time:

15 days after receiving the depositpayment:

T/T

Golin brand bidirectional crowning table for press brake machine

The technical datas and size for your press brake crowning table choose

Production plan

1.Forging Editing the drawing for production

2.Processing rough shape

3.Heat treatment adjustment HRC32-38

4.Processing rough shape and drilling rough holes

5.All body heat treatment HRC47+/-3

6.Grinding the outside shape accurately.

7.Grinding all sizes accurately

8.Inspection

9.Polishing and marking logos

10.Packing

ONLINE

ONLINE 0555-6768298

0555-6768298 0555-6769126

0555-6769126 pressbraketooling@hotmail.com

pressbraketooling@hotmail.com +8615251769225

+8615251769225