0555-6768298

0555-6768298

0555-6768298

0555-6768298

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

Contact Us

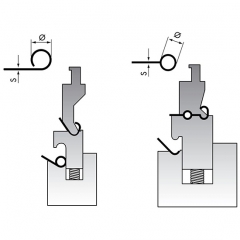

Advantages Production in two or three strokes Reducing of marks through spring loaded hold-down-device Active components are hardened High repeatability through integrated backgauge Functional test and adjustment through test bends - with your sample sheets Suitable For Material thickness up to 4,0 mm minimum inside Ø: 2,5 mm x material thickness for steel and aluminium 3,0 mm x material thickness for stainless steel

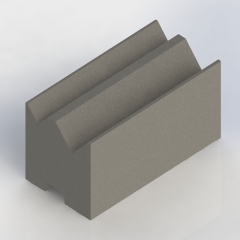

Press brake rolla-v dies without scratch, it's best to put the film on the workpiece surface when you bend. and we will recoomend the suitable roll-v die size for you according to the plate you bend.

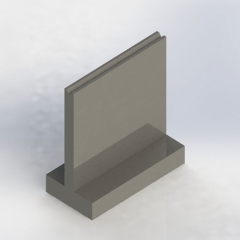

Shim Style Adjustable Dies Adjustable lower dies could be considered to be one of the most versatile additions to a press brake. With this type of tool, openings can be arranged from 6.35mm to 381mm. Spacers are provided to produce the required opening. Slotted spacers allow for easy removal to change the die opening. When not in use, spacers are positioned at sides of the die block. These dies can be furnished in solid lengths or sectioned for easier handling.

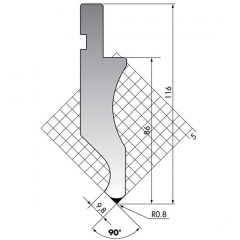

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

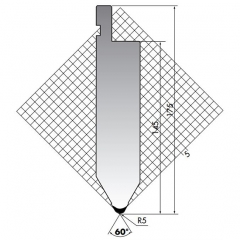

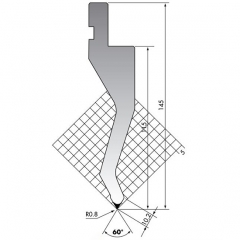

The stright blade size:835*175*40mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

The Amada press brake tooling straight blade size:835*145*32mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

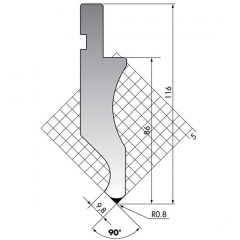

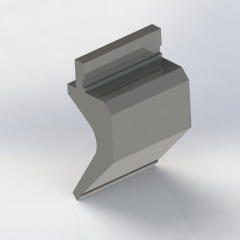

The gooseneck punch size:835*197*92mm,88degree. the material is 42CrMo4, hardness is HRC47+/-3. and height 197mm,width 92mm. can be made according to customer's request.

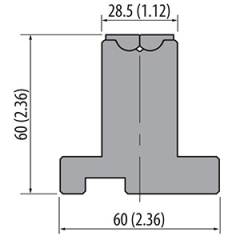

The T-V die size:835*120*60mm,V12,30degree. the material is 42CrMo4, hardness is HRC52-58. and V6,V8,V10,V16,V20,V25 can be made according to customer's request.

The self centering 2V dies, the size is 835*46*50mm,88degree,the weisght is 17kg.and we can make V5-V9,V8-V12,V12-V20,V16-V25 and other V opening according the bending thickness.

In this rapidly evolving era of smart manufacturing, every step of innovation drives the leap forward of the industry. As a leading figure in the field of bending machine mold manufacturing, Golin proudly announces its participation in the 2025 Vietnam Machine Tool Exhibition (MTA Vietnam) with advanced technologies and exceptional products. This is not merely an exhibition; it is the fulfillment of our commitment to global manufacturing and our relentless pursuit of technological innovation.

Since its inception, Golin has always stood at the forefront of bending machine mold design and manufacturing. With exquisite craftsmanship and a rigorous quality control system, we have provided countless efficient, durable, and precise mold solutions for clients worldwide. Our products are widely used in various fields such as automotive manufacturing, aerospace, electronics communications, architectural decoration, and have garnered praise and trust from clients both domestically and internationally.

Technological Innovation: We possess a research and development team composed of industry veterans who continuously explore new materials and processes, ensuring that every mold meets or exceeds client expectations.

Smart Manufacturing: By introducing advanced production equipment and intelligent management systems, we have achieved seamless integration from design to production, enhancing efficiency while ensuring product precision and quality.

Customized Services: Recognizing the uniqueness of each project, we offer one-on-one customized services, tailored to client needs, helping them stand out in the fiercely competitive market.

MTA Vietnam Exhibition: A Dazzling Debut on the Global Stage

MTA Vietnam, as one of the most influential machine tool and tooling exhibitions in Southeast Asia, serves as an excellent platform for showcasing the latest technologies and expanding into international markets. For this exhibition, we have meticulously prepared multiple star products, including but not limited to:

High-Precision Bending Machine Molds: Utilizing the latest alloy materials, these molds significantly enhance wear resistance and service life, suitable for high-precision bending operations of complex surfaces.

Intelligent Control Systems: Integrated with IoT technology, these systems enable remote monitoring and fault prediction, making production management more efficient and convenient.

Eco-Friendly and Energy-Saving Solutions: In response to the call for green manufacturing, we introduce low-energy, high-efficiency mold solutions, contributing to the sustainable development of enterprises.

At MTA 2025, Golin showcases not only products and technologies but also our sincere invitation to global partners. We look forward to in-depth exchanges with industry peers, buyers, and technical experts from around the world, exploring industry trends, sharing successful cases, seeking cooperation opportunities, and jointly advancing manufacturing to higher levels.

Invitation to Witness the Glory

ONLINE

ONLINE 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252