0555-6768298

0555-6768298

0555-6768298

0555-6768298

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

Contact Us

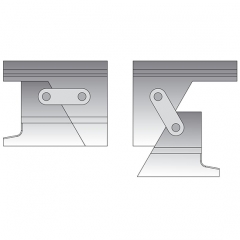

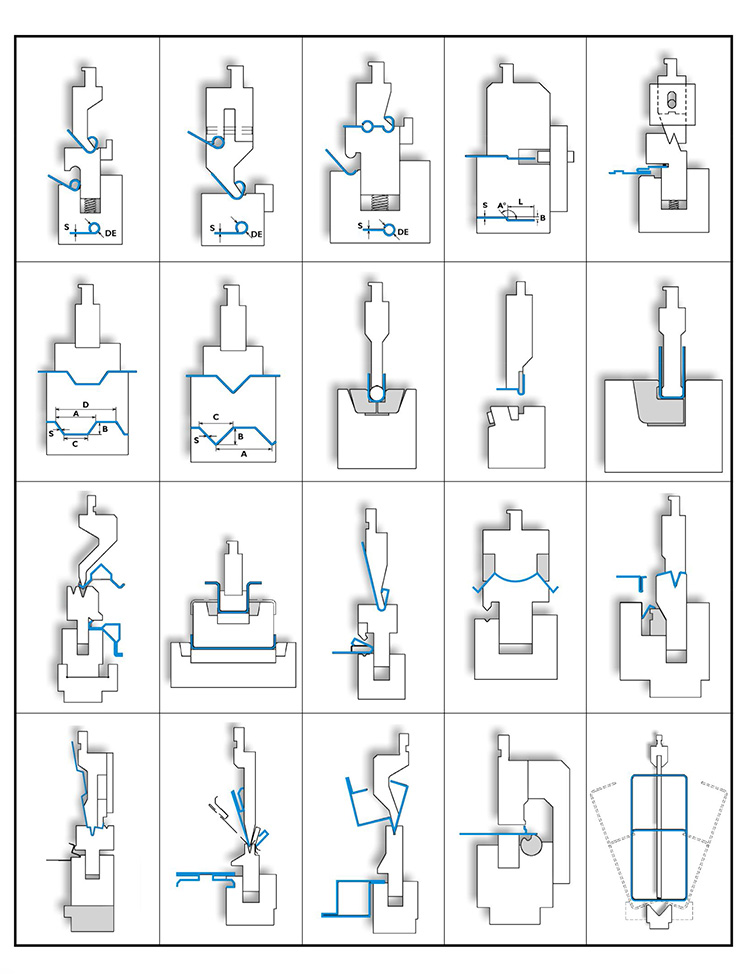

Also known as Z bends or Joggles, the Offset punch and die set is able to make two bends at the same time. This is the solution for applications requiring materials to be joined together or when you need to make a second bend that will not interfere with the first bend.

Advantages ▶ Easy and quick bending of boxes ▶ Easy removal of the finished profile ▶ Compatible with punches/top tools ▶ Individual production possible

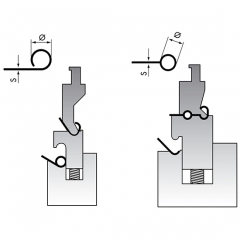

Advantages Production in two or three strokes Reducing of marks through spring loaded hold-down-device Active components are hardened High repeatability through integrated backgauge Functional test and adjustment through test bends - with your sample sheets Suitable For Material thickness up to 4,0 mm minimum inside Ø: 2,5 mm x material thickness for steel and aluminium 3,0 mm x material thickness for stainless steel

Tonnage 150 kN/m max. Material 42Cr: 900-1150 N/mm2 Advantages - Bending of closed profiles can be produced - Large Channel Profiles can be produced - Easy Removal - Individual Production

Press brake rolla-v dies without scratch, it's best to put the film on the workpiece surface when you bend. and we will recoomend the suitable roll-v die size for you according to the plate you bend.

Shim Style Adjustable Dies Adjustable lower dies could be considered to be one of the most versatile additions to a press brake. With this type of tool, openings can be arranged from 6.35mm to 381mm. Spacers are provided to produce the required opening. Slotted spacers allow for easy removal to change the die opening. When not in use, spacers are positioned at sides of the die block. These dies can be furnished in solid lengths or sectioned for easier handling.

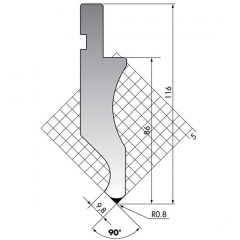

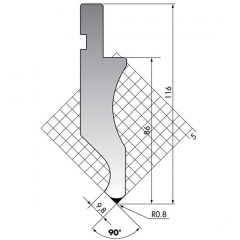

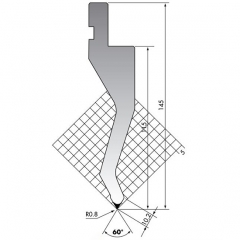

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

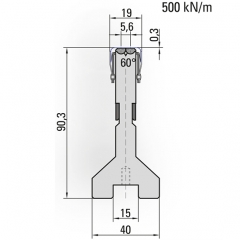

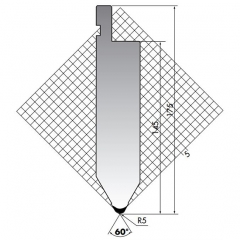

The stright blade size:835*175*40mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*145*32mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

![]() Optimum materials

Optimum materials

![]() Bending radius/intake radii, hardened up to 52–55 HRC

Bending radius/intake radii, hardened up to 52–55 HRC

![]() Precision ground

Precision ground

![]() Guaranteed exchangeability and parallelism

Guaranteed exchangeability and parallelism

![]() Punch/top-tool clamping in two different models

Punch/top-tool clamping in two different models

![]() Self centering

Self centering

![]() Usable on both sides

Usable on both sides

![]() Tool marking with all technical information

Tool marking with all technical information

product origin:

Maanshanbrand:

Golinshipping port:

Shanghai portcolor:

Silverlead time:

15-20 days after receiving the depositpayment:

T/T, Western union

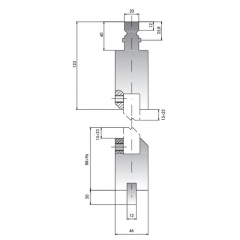

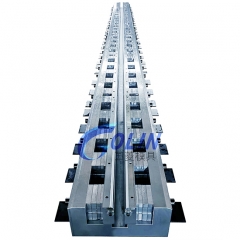

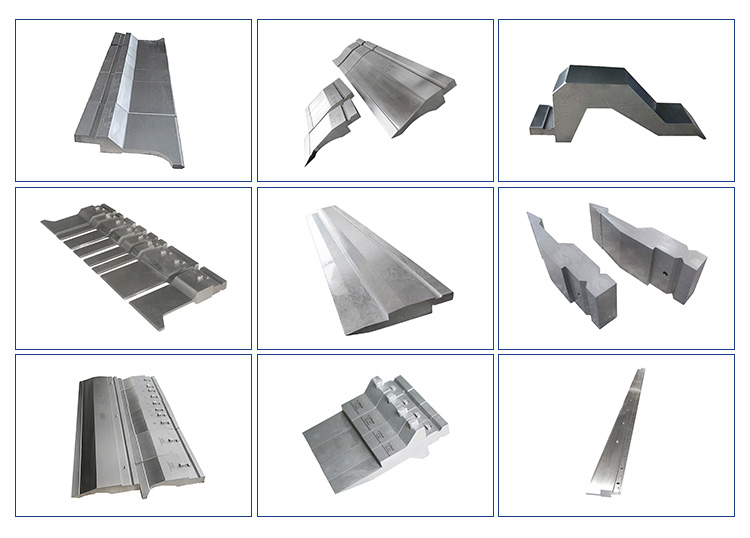

Size: 835 * 220 * 85mm(customizable size)

Material: 42CrMo / C45

Hardness: HRC47+/-3

Quench: Full body heat treatment

Package: Multi plywood

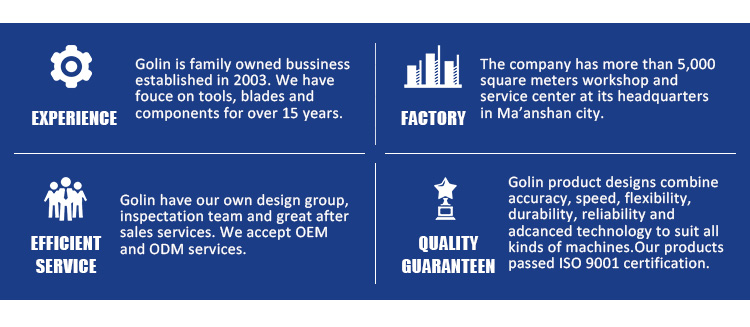

Golin is in the field of sheet metal processing, and is engaged in the production and sale of bending tools and crowning tables. Golin can supply punches and dies for any type of press brake. These tools are made of hardened and ground high quality steels C45 and 42CrMo. Our product range includes tool types such as: Amada / Promecam, Trumpf / Wila, Bystronic/Beyeler, LVD type, American type, Gasparini Type, Colgar Type,Colly Type,Ajial-Axial Type, Hämmerle-bystronic Type,etc. Golin has an in-house R&D department specializing in designing technologically advanced solutions, with the support of our technical department we are able to design and supply special punches and dies and research the right solution for your bending project. The tools our company supplies for press brakes are efficient and durable, thanks to the ability to use cutting-edge technology and the guarantee of highly qualified employees. Reliability and competitive pricing are two other distinguishing features of our bending tools.

SIZE:

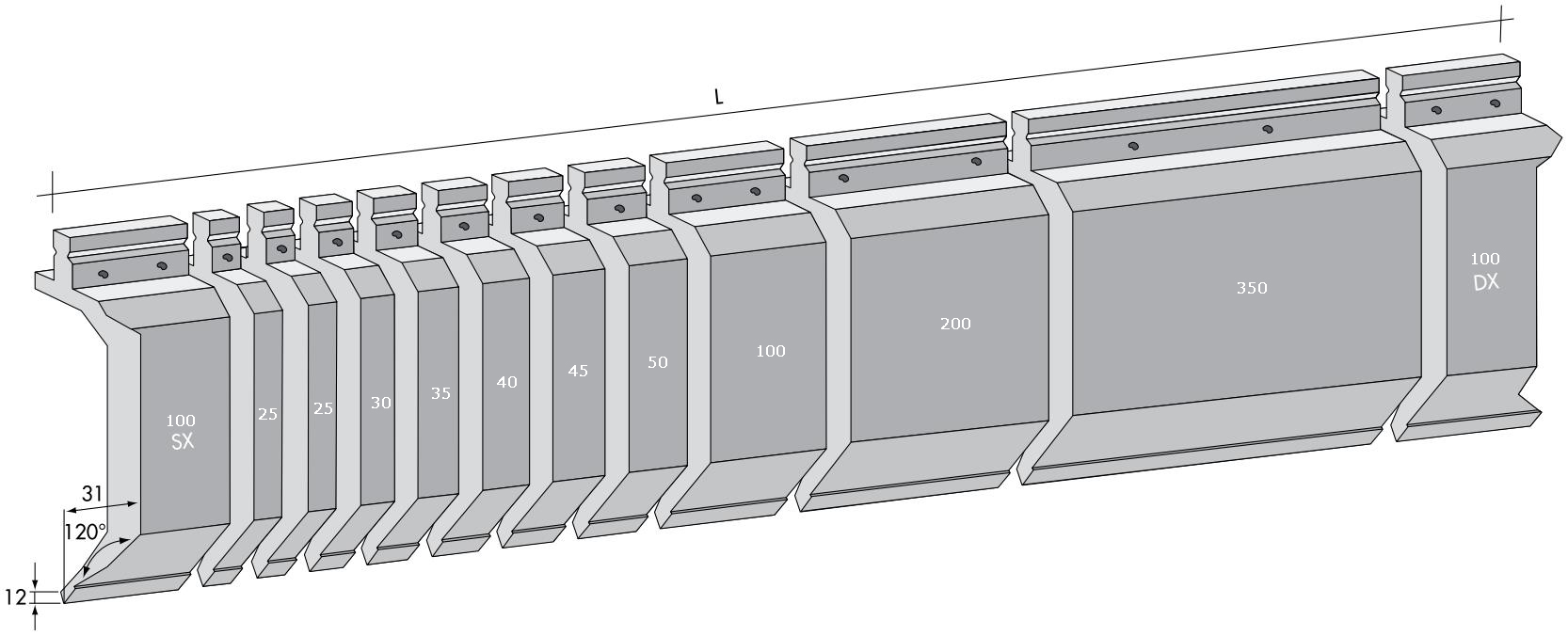

Golin Wila style press brake tooling's standard length is:

Three kinds of 500mm, 835mm and L1100mm. According to the length of the press brake machine worktable, it is used in combination.

The standard segmentation size is:

Upper die: 100 (left) 25, 25, 30, 35, 40, 45, 50, 100, 200, 350, 100 (right) = 1100mm (set)

■In addition to the above standard length, if you need to customize a special length, please explain.

FAQ

1. Q: Are you a factory or trading company? How is you factory extrusion experience?

A: We are a factory. 15 years Manufacturing experience.Leading supplier in Maanshan city.

2. Q:Can you put my brand logo on these products?

A:Yes we can.

3. Q:What is the Minimum Order Quantity (MOQ) for your OEM service?

A:MOQ is 1pcs.

4. Q:When can you ship the products after we make payment?

A:Production time is normally 15-25 days.

ONLINE

ONLINE 0555-6768298

0555-6768298 0555-6769126

0555-6769126 pressbraketooling@hotmail.com

pressbraketooling@hotmail.com +8615251769225

+8615251769225