0555-6768298

0555-6768298

0555-6768298

0555-6768298

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

Contact Us

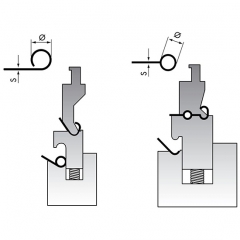

Advantages Production in two or three strokes Reducing of marks through spring loaded hold-down-device Active components are hardened High repeatability through integrated backgauge Functional test and adjustment through test bends - with your sample sheets Suitable For Material thickness up to 4,0 mm minimum inside Ø: 2,5 mm x material thickness for steel and aluminium 3,0 mm x material thickness for stainless steel

Press brake rolla-v dies without scratch, it's best to put the film on the workpiece surface when you bend. and we will recoomend the suitable roll-v die size for you according to the plate you bend.

Shim Style Adjustable Dies Adjustable lower dies could be considered to be one of the most versatile additions to a press brake. With this type of tool, openings can be arranged from 6.35mm to 381mm. Spacers are provided to produce the required opening. Slotted spacers allow for easy removal to change the die opening. When not in use, spacers are positioned at sides of the die block. These dies can be furnished in solid lengths or sectioned for easier handling.

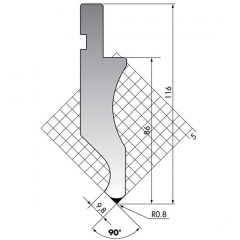

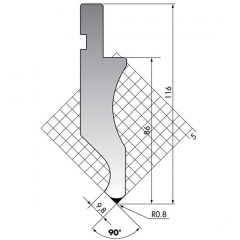

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

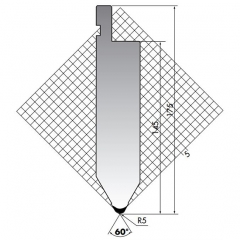

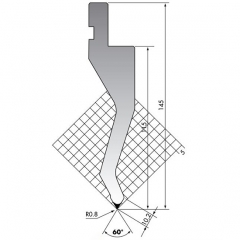

The stright blade size:835*175*40mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

The Amada press brake tooling straight blade size:835*145*32mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

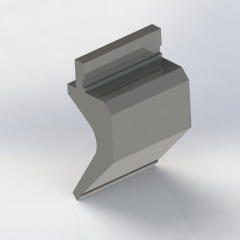

The gooseneck punch size:835*197*92mm,88degree. the material is 42CrMo4, hardness is HRC47+/-3. and height 197mm,width 92mm. can be made according to customer's request.

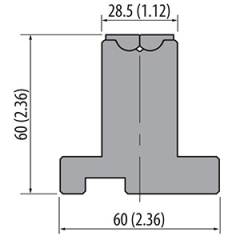

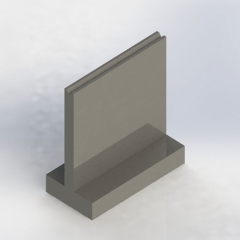

The T-V die size:835*120*60mm,V12,30degree. the material is 42CrMo4, hardness is HRC52-58. and V6,V8,V10,V16,V20,V25 can be made according to customer's request.

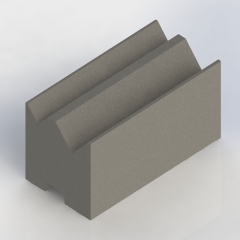

The self centering 2V dies, the size is 835*46*50mm,88degree,the weisght is 17kg.and we can make V5-V9,V8-V12,V12-V20,V16-V25 and other V opening according the bending thickness.

What is the best material for press brake tooling?

In the field of sheet metal fabrication, the material selection of press brake tools directly determines its wear resistance, service life, and forming accuracy. To ensure production efficiency and product quality, it is especially important to choose tooling materials scientifically. However, with so many material options available on the market, customers are often confused when making a decision. So, how can one choose the "best" tooling material? This article will explore the topic from four key perspectives.

Based on Sheet Material Type

Different sheet materials require different tooling materials. The most commonly used press brake Moulds materials on the market include 42CrMo, T8/T10, H13, and SKD11/D2. Among them, high-strength and tough alloy steels like 42CrMo are sufficient for most general bending tasks. However, for materials such as stainless steel, which have higher strength and springback, harder and more wear-resistant tooling materials like SKD11 or H13 are more suitable.

Based on production volume and usage frequency

For long-running production lines or high-frequency operations, it's wise to use more wear-resistant materials like H13 or SKD11. While these come at a higher upfront cost, they significantly reduce downtime and tooling replacement. For short runs or occasional use, 42CrMo offers a great balance of performance and affordability.

Based on precision requirements

High-precision sheet metal parts often require higher hardness and stability from the tooling. In such cases, it is recommended to use high-hardness materials like SKD11 to prevent deformation and maintain consistent bending angles over time. Tooling with lower hardness is more likely to wear out or deform with prolonged use, which can negatively impact product accuracy.

Based on Cost

In general, high-quality tooling materials tend to be more expensive, but they offer a longer service life and require less maintenance. In the long run, despite the higher initial investment, the overall cost of use is actually lower. For customers who prioritize efficiency and stability, choosing high-grade materials is a wise investment.

In conclusion, there is no single standard answer when it comes to selecting press brake tooling materials. The right choice should be based on a comprehensive evaluation of material type, production goals, quality requirements, and budget.

At Golin, we are committed to using high-quality materials such as 42CrMo and SKD11, combined with advanced heat treatment processes to ensure our tools are both strong and durable. We also offer customized material and hardness options tailored to our customers' specific bending needs.If you have any further questions or would like to learn more, feel free to contact us anytime!

ONLINE

ONLINE 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252