0555-6768298

0555-6768298

0555-6768298

0555-6768298

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

Contact Us

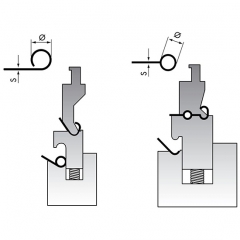

Advantages Production in two or three strokes Reducing of marks through spring loaded hold-down-device Active components are hardened High repeatability through integrated backgauge Functional test and adjustment through test bends - with your sample sheets Suitable For Material thickness up to 4,0 mm minimum inside Ø: 2,5 mm x material thickness for steel and aluminium 3,0 mm x material thickness for stainless steel

Press brake rolla-v dies without scratch, it's best to put the film on the workpiece surface when you bend. and we will recoomend the suitable roll-v die size for you according to the plate you bend.

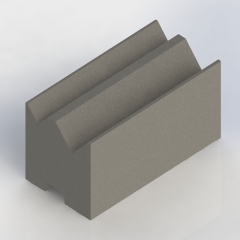

Shim Style Adjustable Dies Adjustable lower dies could be considered to be one of the most versatile additions to a press brake. With this type of tool, openings can be arranged from 6.35mm to 381mm. Spacers are provided to produce the required opening. Slotted spacers allow for easy removal to change the die opening. When not in use, spacers are positioned at sides of the die block. These dies can be furnished in solid lengths or sectioned for easier handling.

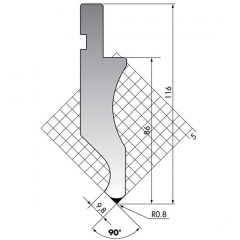

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

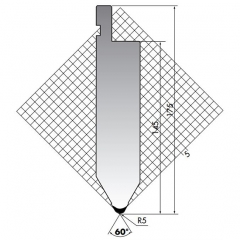

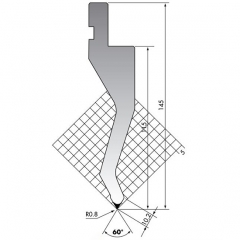

The stright blade size:835*175*40mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

The Amada press brake tooling straight blade size:835*145*32mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

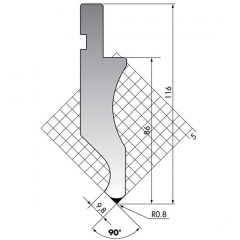

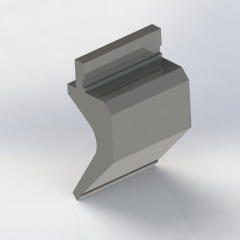

The gooseneck punch size:835*197*92mm,88degree. the material is 42CrMo4, hardness is HRC47+/-3. and height 197mm,width 92mm. can be made according to customer's request.

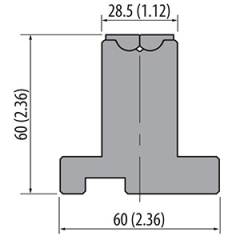

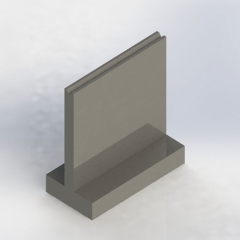

The T-V die size:835*120*60mm,V12,30degree. the material is 42CrMo4, hardness is HRC52-58. and V6,V8,V10,V16,V20,V25 can be made according to customer's request.

The self centering 2V dies, the size is 835*46*50mm,88degree,the weisght is 17kg.and we can make V5-V9,V8-V12,V12-V20,V16-V25 and other V opening according the bending thickness.

As a leading manufacturer of press brake tooling, we have achieved remarkable progress in recent years. Now, with our annual output value poised to exceed 100 million, our business is no longer confined to the domestic market. We are actively expanding into international markets and will be participating in industry exhibitions across Brazil, Poland, Mexico, Vietnam, and Turkey this year, showcasing our technology and capabilities to the world.

State-of-the-Art Equipment and Rigorous Quality Control

Within our factory, we have invested in top-of-the-line production equipment and cutting-edge technology. These machines not only enhance our production efficiency but also ensure the high precision and quality of our products. Every set of tooling undergoes a strict quality control process to ensure that our customers receive reliable and durable products.

We understand that quality is the lifeblood of any business. To ensure every tooling meets customer requirements, we strictly adhere to international standards at every production step, striving for perfection. Whether it’s precision, durability, or ease of use, our press brake tooling performs exceptionally well in even the most complex production environments.

Global Reach and Focus on International Trade

With the acceleration of globalization, we have set our sights on expanding into international markets. By participating in major international exhibitions, we not only have the opportunity to showcase our products but also to connect with industry leaders and potential customers worldwide. These interactions help us understand market demands better, enabling us to continually improve our technology and services.

This year, we will actively participate in exhibitions in Brazil, Poland, Mexico, Vietnam, and Turkey. Through these events, we aim to not only promote our brand but also gain deeper insights into the global market trends, laying a solid foundation for future international collaborations.

Looking to the Future

Our goal is not only to be the leader in our domestic industry but also to establish a strong presence on the global stage. With continuous innovation and improvement, we believe our company is on track for an even brighter future. Moving forward, we will focus on enhancing our technological research and development as well as expanding our international market presence, aiming to become a benchmark in the global press brake tooling industry.

We firmly believe that only by constantly pursuing excellence can we stand out in the competitive market. Behind the production of every tooling is our commitment to quality, our dedication to customer satisfaction, and our confidence in the future. As we move forward, we will continue to craft every tooling with care, providing more efficient and precise solutions to our global customers.

ONLINE

ONLINE 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252