0555-6768298

0555-6768298

0555-6768298

0555-6768298

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!

Contact Us

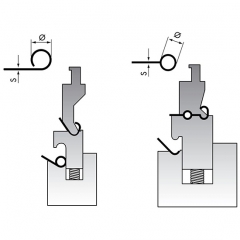

Advantages Production in two or three strokes Reducing of marks through spring loaded hold-down-device Active components are hardened High repeatability through integrated backgauge Functional test and adjustment through test bends - with your sample sheets Suitable For Material thickness up to 4,0 mm minimum inside Ø: 2,5 mm x material thickness for steel and aluminium 3,0 mm x material thickness for stainless steel

Press brake rolla-v dies without scratch, it's best to put the film on the workpiece surface when you bend. and we will recoomend the suitable roll-v die size for you according to the plate you bend.

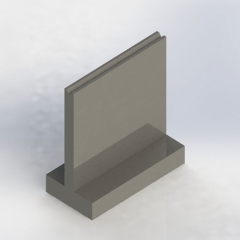

Shim Style Adjustable Dies Adjustable lower dies could be considered to be one of the most versatile additions to a press brake. With this type of tool, openings can be arranged from 6.35mm to 381mm. Spacers are provided to produce the required opening. Slotted spacers allow for easy removal to change the die opening. When not in use, spacers are positioned at sides of the die block. These dies can be furnished in solid lengths or sectioned for easier handling.

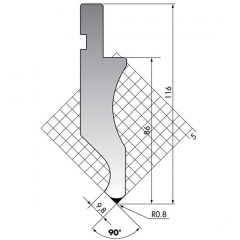

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

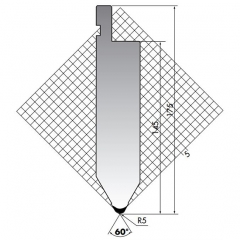

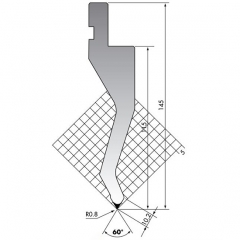

The stright blade size:835*175*40mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

The stright blade size:835*146*26mm,90degree. the material is 42CrMo4, hardness is HRC47+/-3

The Amada press brake tooling straight blade size:835*145*32mm,60degree. the material is 42CrMo4, hardness is HRC47+/-3

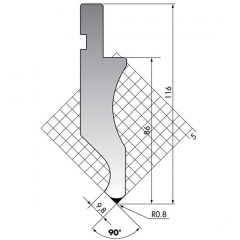

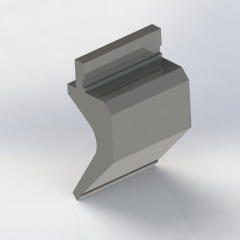

The gooseneck punch size:835*197*92mm,88degree. the material is 42CrMo4, hardness is HRC47+/-3. and height 197mm,width 92mm. can be made according to customer's request.

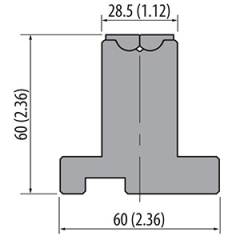

The T-V die size:835*120*60mm,V12,30degree. the material is 42CrMo4, hardness is HRC52-58. and V6,V8,V10,V16,V20,V25 can be made according to customer's request.

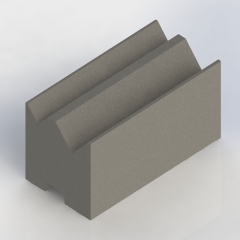

The self centering 2V dies, the size is 835*46*50mm,88degree,the weisght is 17kg.and we can make V5-V9,V8-V12,V12-V20,V16-V25 and other V opening according the bending thickness.

Golin’s Press Brake Tooling: Paving the Way for Precision and Efficiency in 2025

As we welcome 2025, Golin is excited to continue our commitment to providing high-quality press brake tooling for industries worldwide. With a rich history of craftsmanship and innovation, we’re proud to lead the way in producing precision tooling that enables manufacturers to meet their bending needs with confidence and efficiency.

Why Choose Golin’s Press Brake Tooling?

At Golin, we understand that precision, durability, and performance are the key drivers for success in the world of metal fabrication. Our press brake tooling is engineered to meet the most stringent industry standards and designed to work seamlessly with a variety of press brake machines. Whether you’re working with mild steel, stainless steel, or aluminum, our tooling ensures perfect bends every time.

1. Superior Quality and Durability

Every piece of tooling we produce is crafted with premium materials and undergoes rigorous testing to ensure it meets our high standards. We know that in a fast-paced production environment, downtime is costly. That’s why Golin press brake tooling is built to last, ensuring minimal wear and tear over time.

2. Versatility for Diverse Applications

From simple to complex bending requirements, our tooling solutions are versatile and adaptable, offering exceptional performance for a wide range of applications. No matter the challenge, Golin’s tooling is up to the task, providing solutions for everything from intricate designs to high-volume production runs.

3. Custom Solutions for Your Needs

At Golin, we believe in offering tailored solutions to meet the unique needs of our customers. Whether you're looking for standard tooling or custom-built options, our team works closely with you to ensure the best fit for your production line. This personalized approach guarantees that our tooling will optimize your bending processes.

4. Supporting Your Growth in 2025

As we move into the new year, Golin is dedicated to supporting your growth and success. With ongoing product innovation and a focus on customer satisfaction, we’re here to ensure that your press brake tooling needs are met with top-tier products and services.

Looking Ahead

In 2025, Golin will continue to build on our legacy of excellence by introducing new products and refining our existing offerings to meet the evolving demands of the market. We’re excited to work with you to tackle new challenges and take your metal forming processes to the next level.

Whether you are a manufacturer looking for high-quality press brake tooling or a company interested in customizing solutions for your specific needs, Golin is here to provide the tools for your success.

Contact Us Today

Let us help you find the perfect tooling solution for your business. Contact Golin to discuss how our press brake tooling can enhance your operations in 2025 and beyond.

ONLINE

ONLINE 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252